Anti-Harmonic Intelligent Integrated Power Capacitor Compensation Device

Anti-Harmonic Intelligent Integrated Power Capacitor Compensation Device

Industry Background and Market Demand

Modern industrial and commercial power networks face increasing challenges in reactive power management due to the widespread use of nonlinear loads, including variable frequency drives, rectifiers, welding equipment, and motor drives. These devices introduce reactive currents and harmonics, causing voltage distortion, reduced power factor, and increased losses in transformers and distribution systems. In this context, smart capacitor controllers have emerged as essential tools to optimize reactive power compensation and maintain stable voltage profiles...

-

Бүлешергә:

Бәйләнешкә инегеҙ

Онлайн-запрос

-

Core Concept and Key Technical Principles

A Controllers Smart Capacitor combines Reactive Power Compensation with automated control and protective functions. Its primary functions include:

Reactive Power Compensation – Balances the phase difference between voltage and current to improve system power factor, reduce line losses, and optimize transformer loading.

Harmonic Protection and Suppression – The system incorporates protection mechanisms against overharmonics, ensuring stable voltage waveforms and mitigating adverse effects on sensitive equipment.

Advanced Protection Features – Equipped with zero-crossing switching, overtemperature protection, phase-loss detection, overvoltage and undervoltage protection to ensure safe operation under abnormal conditions.

Self-Diagnostics and Fault Management – Integrated LCD screens display fault conditions in Chinese and provide real-time self-diagnosis to facilitate rapid on-site troubleshooting.

The controller adjusts compensation dynamically, allowing incremental increases in capacity without physical rewiring. This modular, scalable design provides flexibility for system expansion as load requirements evolve, making it ideal for industrial facilities with variable demand.

Product Structure, Performance, Materials, and Manufacturing

Structural Overview

Controllers Smart Capacitors are composed of the following components:

Capacitor Modules – Constructed with metallized film or high-quality dielectric materials, offering high insulation strength, minimal leakage, and long service life.

Controller Unit – Houses microcontroller-based circuits to monitor voltage, current, and harmonic levels, and execute control logic for automatic switching and protection.

Series Reactor (if applicable) – Limits inrush currents during switching and suppresses harmonic resonance, enhancing system stability.

LCD Display Interface – Provides fault codes, real-time operating status, and diagnostic feedback for efficient maintenance.

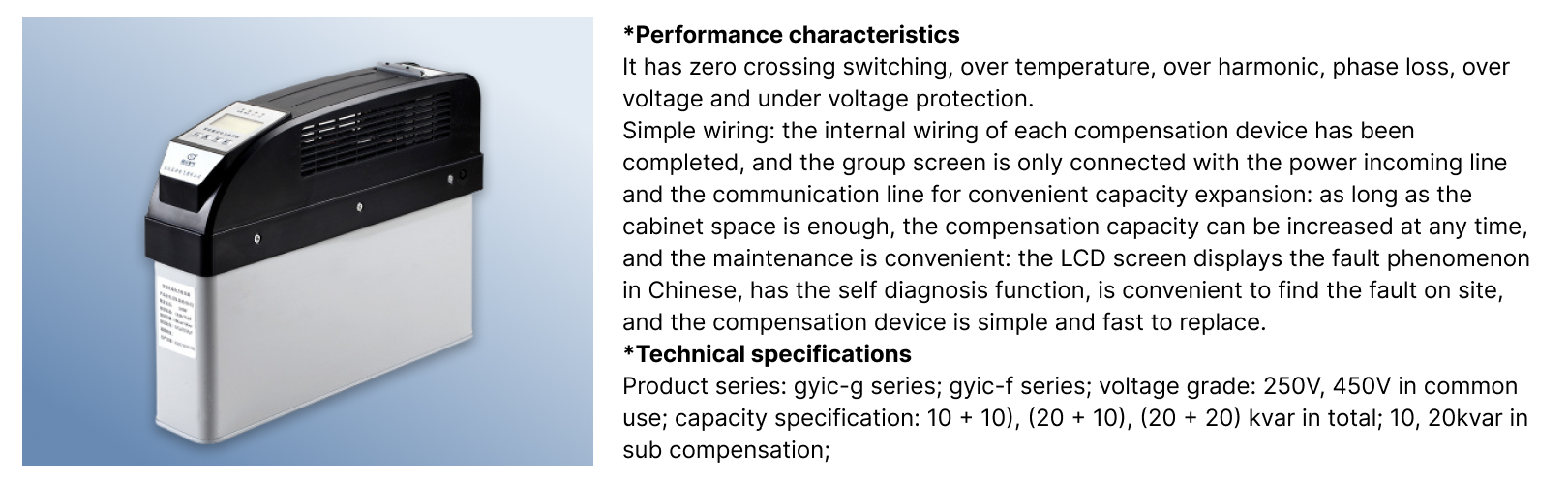

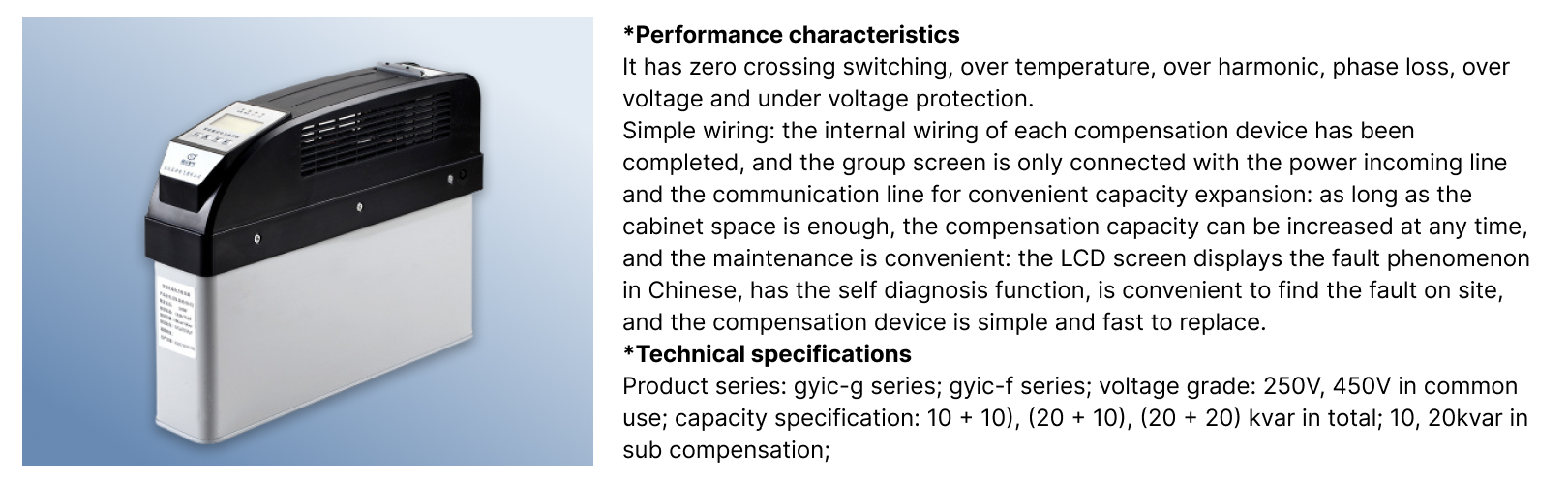

Performance Characteristics

Voltage Ratings: Commonly 250 V and 450 V, adaptable to low-voltage industrial systems.

Capacity Ratings: Total compensation configurations of (10 + 10), (20 + 10), (20 + 20) kvar, with sub-compensation options of 10 or 20 kvar.

Switching Technology: Zero-crossing switching reduces inrush currents and minimizes transient overvoltages.

Protection Functions: Comprehensive monitoring for overtemperature, overharmonics, phase loss, overvoltage, and undervoltage.

Maintenance and Expansion: Modular design allows convenient capacity increase within available cabinet space, and quick replacement of defective modules.

Materials and Manufacturing

High-reliability capacitors are manufactured using film-based dielectric materials with precise metallization and encapsulation to prevent moisture ingress and ensure thermal stability. Control boards use high-quality PCBs, low-tolerance components, and robust connectors for electrical reliability. Series Reactors, when incorporated, are made of high-grade silicon steel laminations to minimize losses and maintain magnetic stability under continuous duty.

Key Factors Affecting Quality and Performance

The performance and longevity of Controllers Smart Capacitors depend on several critical factors:

Voltage Matching: Proper selection of capacitor voltage rating above maximum operating voltage is essential to prevent dielectric stress and ensure longevity.

Harmonic Environment Analysis: Understanding the harmonic spectrum of the facility is crucial to select appropriate reactors or filters and prevent resonance.

Thermal Management: Adequate airflow within the cabinet and heat-resistant components reduce the risk of overheating.

Switching Precision: Zero-crossing technology minimizes voltage spikes and mechanical stress on the capacitor.

Control Algorithm Accuracy: The microcontroller’s real-time monitoring and compensation algorithms directly influence the system’s reactive power correction efficiency.

Supply Chain and Supplier Selection Criteria

For industrial applications, selecting a reliable supplier is paramount:

Compliance and Certification: Suppliers should offer IEC, ISO, or equivalent certifications ensuring compliance with safety and quality standards.

Documentation and Technical Support: Comprehensive wiring diagrams, installation instructions, and engineering guidance are essential for correct implementation.

Component Quality Assurance: Traceable sourcing of dielectric films, reactor cores, and electronic components enhances reliability.

Scalability and Service: Suppliers offering modular solutions, on-site commissioning support, and rapid after-sales response are preferred.

Long-term Maintenance: Availability of replacement modules and diagnostic tools ensures minimal downtime during faults.

Common Challenges and Industry Pain Points

Harmonic Distortion: Nonlinear loads can create high-order harmonics. While the controller protects against overharmonics, site analysis is necessary to prevent resonance issues.

Inrush Currents: Large capacitor banks may experience inrush currents during switching. Proper reactor selection and zero-crossing switching are essential.

Fault Diagnosis: On-site troubleshooting without integrated diagnostics can be time-consuming. LCD self-diagnosis significantly reduces maintenance complexity.

Capacity Planning: Over- or under-compensation can lead to inefficient energy use or system instability, requiring careful sizing and system monitoring.

Application Scenarios and Industry Use Cases

Industrial Manufacturing Plants – Heavy motors and dynamic production equipment create fluctuating reactive power demand; smart capacitors stabilize voltage and maintain power factor.

Renewable Energy Facilities – Integration with inverters and variable renewable sources requires dynamic compensation for grid stability.

Commercial Buildings and Data Centers – Sensitive electronics benefit from reduced voltage fluctuation and improved energy efficiency.

Distribution Substations – Smart capacitors can optimize low-voltage reactive power compensation, reducing losses and supporting network voltage regulation.

Current Trends and Future Directions

Digital Monitoring and IoT Integration: Remote monitoring and predictive diagnostics enable proactive maintenance and performance optimization.

Modular and Scalable Architectures: Increasing adoption of modular capacitor units allows flexible system expansion without major redesign.

Hybrid Compensation Solutions: Combining smart capacitors with active filters addresses both reactive power and harmonic mitigation comprehensively.

Advanced Materials and Thermal Design: Improved dielectric films and core materials enhance durability, reduce losses, and enable higher-density installations.

Frequently Asked Questions (FAQ)

Q: What is the advantage of using a smart capacitor controller over a traditional capacitor bank?

A: Smart controllers provide dynamic, real-time compensation, automated protection, and fault diagnostics, unlike static capacitor banks with fixed compensation steps.

Q: Can the system expand capacity easily?

A: Yes, modular design allows incremental capacity addition as long as cabinet space is available.

Q: How does the LCD screen help in maintenance?

A: The LCD displays faults in Chinese and provides self-diagnosis, allowing operators to quickly locate issues and replace defective modules efficiently.

English

English

Español

Español

Portugues

Portugues

Pусский

Pусский

Français

Français

Deutsch

Deutsch

日本語

日本語

한국어

한국어

العربية

العربية

Italiano

Italiano

Nederlands

Nederlands

Svenska

Svenska

Polski

Polski

Türk dili

Türk dili

हिन्दी

हिन्दी

Indonesia

Indonesia

Melayu

Melayu

dansk

dansk

Magyar

Magyar

қазақ

қазақ

বাংলা

বাংলা

עִברִית

עִברִית

čeština

čeština

українська

українська

беларускі

беларускі

Filipino

Filipino

Suomalainen

Suomalainen

اردو

اردو

հայերեն

հայերեն

български

български

Hrvatski

Hrvatski

galego

galego

नेपाल

नेपाल

euskara

euskara

Shqipëria

Shqipëria

Malagasy

Malagasy

Türkmenler

Türkmenler

Ilocano

Ilocano

Нохчийн

Нохчийн

Ватсап

Ватсап Телефон

Телефон